Did you know that the origins of metal marking go back as far as 500,000 years ago, not long after the ancient Greek discovered fire?

Since then, there have been outstanding advancements in metal marking equipment.

From the crude hammer-and-anvil method to high-tech and ultra-portable dot peen marking machines, quite a lot of innovations have taken place.

Now, a need is arising for more customized solutions and products among manufacturing and industrial companies.

This demand has led to a marked increase in the use of metal marking equipment for product customization. It has gone beyond simply imprinting a figure or a sign on a metal; metal marking has now become highly customizable.

You can now design a logo, mark very sophisticated signs, and achieve many more amazing things. These and other possibilities will be discussed in this post.

We also provide a detailed overview of the latest metal marking technologies, explore their features, and consider how to make the right choice for your company.

The Latest Metal Marking Technologies In 2018

Actually, the term “metal marking” encompasses several different operations and methods of creating signs on metals using machines. Thus, there is a wide variety of marking tools and equipment that you can use.

The latest Innovations in metal marking equipment include fiber laser engravers, handheld dot peen marker machines, and handheld inkjet printers.

These machines have various features and applications across different sectors, but are of particular use to the manufacturing and industrial sectors.

Below, we have described these latest equipment marking tools along with reviews and discussions of their possible applications.

Fiber Laser Marking Machine

Since 1963, when the first laser machine was produced, laser technology has come a long way. It is now being applied for marking metals.

Laser technology uses heat released by a radiated beam to carry out different operations and alter the surface of the material to be marked.

The fiber laser engraver represents a more advanced breakthrough in laser marking.

Here’s how it works…

The core of the fiber is mixed with a rare-earth element, such as Erbium, to dope the fiber. Doped fiber can absorb higher-wavelength photons and has increased conductivity.

The fiber core is then supplied with a light source – in this case, a stack of several LED lasers. This excites the electrons within the fiber core.

The result is a strong beam that can be used to carry out different operations on a metal. These operations include:

Annealing marking: A process used on stainless steel to create signs by altering the surface’s color. This alteration is possible because of the heat from the fiber laser marker. The heat oxidizes the surface of the stainless steel, thereby causing a color change.

Laser engraving: Engraving is a process that entails removing part of the material’s surface to form a definite mark. In this case, the engraving is done by the laser beam on the metal, the heat from the radiated beam melts the surface to “engrave” a mark.

Removing: This process is used to mark coated metals. As the laser beam touches the surface of the metal, it removes the coat and exposes the metal beneath. In this manner, a design can be clearly marked out on the material.

In essence, fiber lasers offer much better performance than other laser marking equipment in terms of mode of operation and efficiency.

Fiber Laser Marking vs. Other Laser Marking Technologies

- Fiber lasers are more stable, since the heat beam is generated within the fiber and no extra optics are used.

- Fiber lasers also produce a very precise, refined laser beam. This is as a result of the beams being produced from the confined fiber core.

- Fiber lasers cool down very easily, but can produce lots of power (even up to 1000 watts).

A perfect example of a fiber laser machine is the HS-FL30 made by Heatsign, which offers the following features:

- It has very low levels of power consumption.

- It has an advanced air cooling system.

- It can mark any kind of metal.

- It has a very high marking speed.

- It is very durable and can work more than 100,000 hours.

- It supports a 24-hour continuous workload.

- It is relatively easy to install and operate.

- No consumables are required for its operation.

3D Laser Marking

Another of the exceptional innovations in modern metal marking is 3D laser marking.

What does it involve?

3D engraving involves making product marks and signs on a non-planar surface. This means engraving on uneven surfaces, spherical surfaces, and cylindrical surfaces.

This is achieved with a digitally controlled laser beam from a HeatSign high-speed laser engraving machine with 3D galvanometer scanner. These machines are fast and efficient; they will produce durable results while saving you valuable time.

Overall, laser marking offers the following advantages and drawbacks:

Pros

- Laser marking machines have high precision.

- They are quite easy to operate.

- They have a low maintenance cost.

- You can use them to mark other materials besides metals, such as plastic

- They create permanent marks on metals.

Cons

- The machines can be quite expensive.

- Operators have to follow some safety precautions.

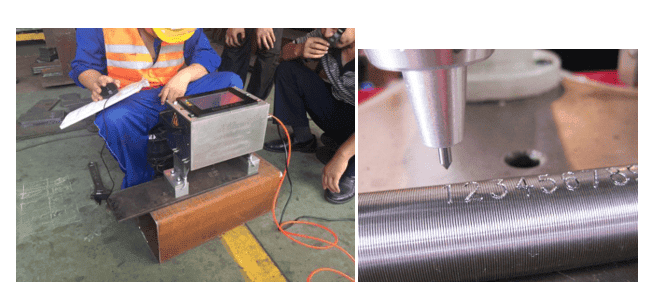

Handheld Dot Peen Marking Machine

Dot peen technology came into existence about 30 years ago, thanks to the innovation of Technifor. These machines perform marking by leveraging the principles of pneumatics and electromagnetics.

How does it work?

A stylus is controlled by the machine to create impact marks or dot-like patterns on any desired material. The stylus has a tip made of diamond or carbide. This allows you to make marks even on very hard materials.

In recent times, technological innovations have revolutionized dot peen marking machines. For example, there are now portable hand-held versions. These function well as portable metal marking equipment whilst retaining the functionality of a traditional dot peen marking machine.

A perfect example of a handheld dot peen marking machine is the HS-PE series by Heatsign. Here’s why this portable machine can help your business:

- It does not require a PC to operate.

- It works perfectly without the use of an air compressor.

- It can be used to create permanent marks.

- It can also work with a backup battery configuration.

- It marks very quickly and efficiently.

- It comes with easy-to-use, intuitive, pre-installed software.

- It can be programmed to mark English letters, numerics, 2D matrix codes, logos, etc.

HEF Technology

This is a new technological development incorporated into Heatsign’s handheld dot peen markers.

HEF allows you to use Heatsign handheld dot peen marker models on uneven surfaces(height differ within 4mm), such as cylindrical products like tubes and pipe. This introduces a great amount of flexibility.

HEF technology does not require any computer in order to function; the software is integrated into touch screen within the portable marker

In all, these are the pros and cons of dot peen marking machines.

Pros

- Dot peen marking machines are very efficient and easy to use.

- They are affordable to buy and also inexpensive to run.

- You can use them to mark various metal parts.

- They create permanent marks.

Cons

- You will need to regularly replace the stylus

Handheld Inkjet Printer

The handheld Inkjet printer is another significant advancement in metal marking technology, offering incredible flexibility, usability, and speed of printing.

Every production and packaging line needs this marking technology.

Handheld inkjet printers feature the following advantages:

- They are lightweight. The total weight of a basic handheld inkjet printer, including the ink cartridge, is about 550g; other products often weigh over 1kg.

- You don’t have to spend much on consumables. The only consumable is a fast-drying cartridge, which goes for USD 70 and can print more than 10,0000 characters.

- It has an embedded processor. You can easily control both the system and the font you want to use. The machine uses a real-time operating system that is stable and doesn’t crash. It also boots quickly relative to other machines.

- The handheld inkjet printer system comes with multiple fonts. You can input any English character, date, batch number, serial number, QR code, barcode, etc.

- It has a built-in large-capacity flash. This allows the machine to store print information for multiple projects. You don’t need to constantly repeat inputs; you can easily switch between designs at any time.

- It is easily integrated it into your production line.

- It and easy to use and ideal for simple tasks like small content, serial numbers, 2D code, one logo etc.

There you have it!

These technologies have changed the way metal marking is carried out in today’s world. More sophisticated designs, higher precision, and several other features have totally changed the way companies and manufacturers customize their products.

Are you wondering which of these machines is the perfect solution for your industrial or manufacturing process?

How to Choose the Right Metal Marking Device

When choosing from among these different metal marking systems, you should carefully consider the following factors:

The type of metal to mark: Sometimes, the best approach to decision-making is to start off by focusing on the end product. What type of metal do you want to mark? How hard is that metal?

Some machines are perfect for hard metals, while others won’t be able to mark them effectively.

Dot peen and fiber laser marking machines work well on hard metals, whereas inkjet printing does not.

Application: What will the marked metal be used for? What kind of environment would it be exposed to? Would the relevant parts of the metal be subjected to wear and tear?

Answering these questions will help you determine which type of metal marking method to use, and then the type of machine to choose.

For instance, if a product is designed for use in very harsh conditions, using a fiber laser engraver or handheld dot peen is preferable over a handheld inkjet printer.

Speed: if your company is focused on timing or if you have a fast production line, a laser marker handheld inkjet printer would be the best option because it’s fast and easy to use.

Some of the other products also have relatively good speed.

Capital cost and running cost: Your budget as a company is also an important factor to consider. Aside from the cost of acquiring any of these machines, you should also consider the maintenance costs and the consumables that would be involved through your use of the device.

Fiber laser marking machines don’t use any consumables. Dot peen markers, on the other hand require the stylus to be replaced periodically, just as handheld inkjet printers will need new cartridges.

Considering all these factors should help you make the choice that best suits your needs.

Heatsign, as a company, is innovation-driven, product-specific, and customer-oriented. They want to give your industrial and manufacturing line the best solutions in metal marking.