Oil and Gas production is a very complex venture. It involves a large amount of data to analyze and multiple Engineering and non-Engineering disciplines need to collaborate to deliver needed results.

Optimising all these assets for the optimum profitability of an oil and gas production operation is one of the biggest challenge facing the industry. The role of digital oilfields is to use latest technologies to provide solutions that solve these challenges.

Now, let us dive in deeper into digital oilfields.

What is Digital Oilfields

Digital Oilfields encompasses all solutions that uses latest technologies to analyse the huge amount of data from the field for timely and accurate decision making and create a coherent workflow for the operational efficiency of oil and gas production.

They are more or less like ERP solutions for oil and gas companies.

Digital Oilfields solutions like FutureOn digital oilfield uses cloud based technologies to capture data from different data sources. This data is integrated and maintained in one place and accessible from anywhere in the world to anyone with the required permission to access them.

Just like in ERP (Enterprise Resource Planning) solutions, data integration is one of the key roles of digital oilfields. Traditionally, data was compartmentalized with each department and engineering discipline storing and maintaining its data in isolation of other departments.

This means that the engineering teams were interpreting their isolated data and taking decisions without having a good picture of how such decision would affect the workflow of other engineering teams.

Digital oilfields integrate data streams from different data sources in one place, making them accessible to everyone that need the data. This leads to collaboration of members across multiple teams, engineering disciplines, and departments, leading to more accurate data analysis for production optimisation and greater operational efficiency.

Why Oil and Gas Companies need Digital Oilfields

Engineers spend a lot of time capturing, organising and validating data, but digital oilfields paired with smart technologies like Internet of Things (IoT) sensors can automate and speed up the process.

Without a digital solution the massive amount of data generated by sensors in the field are virtually impossible to analyze in a cost effective way, which would result in loads of unused data.

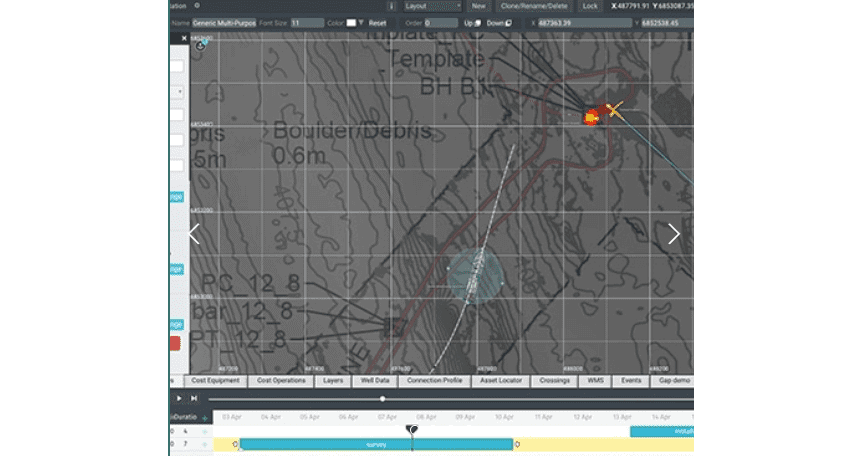

This could result in a number of critical problems being missed by engineers. Solutions like FieldTwin and FieldAP are designed to take-in this massive influx of data and identify discrepancies on the spot.

Latest platforms use artificial intelligence and machine learning to extract useful information from the massive data streams in real time.

The software create a visual presentation of the data through the entire lifecycle. Teams can even set parameters that can trigger warning and notification if set levels are reached or exceeded.

The data can be visualized in 2D or 3D, which enables engineers to explore the data from different perspective leading to a more thorough understanding of the data.

The beauty of it all is that this can be done in collaboration with your colleagues from all over the world and with each bringing their own wealth of experience.

Implementing Digital Oilfields

Thus far, we have highlighted the benefits of digital oilfields to oil and gas companies. One hurdle to adopting these system is the cost of implementation.

Do you need to deploy new hardware and abandon existing systems to take advantage of operational efficiency of the platform.

This is why the focus when implementing digital oilfields is to find an implementation that can easily be integrated to your current systems leading a lower cost of entry.

Solutions like FieldTwin from FutureOn boasts of such seamless implementation.