It is vital to keep in mind while working with adhesive dispensing systems that the ultimate goal is to deliver good quality joints for structural applications. In order to accomplish the required quality of joints that are held by adhesive, you need to utilize automated systems. If you want to know why and how adhesive dispensing robots are used, you’ve clicked on the right post.

In case of robotic adhesive dispensing system, it is necessary to choose the right robot integrator as it decides the final performance of the system.

Making a single wrong decision will have an impact on the ROI (Return on Investment) and will also lead to weak revenues and gross inefficiency. Here’s what you should know on this.

Adhesive Dispensing System – Finding ROI

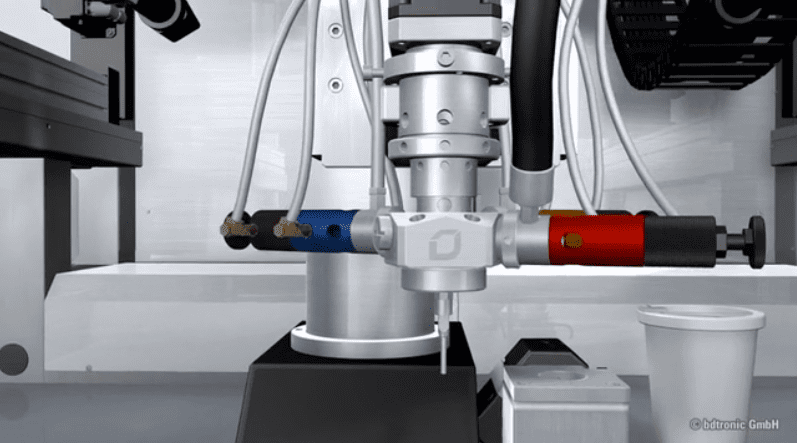

The automated dispensing systems require being precise where it is programmed down to millimeter to be able to accurately and evenly dispense adhesives. In case there is no accuracy in this, profits will be diminished to rework and cleaning.

Similarly, the robotic adhesive system should also be repeatable and persistent. It is due to reduced errors and improved uptime that the productivity of the system is decided. Hence they should be profitable and consistent.

These adhesive balancing systems should also balance this requirement for consistency and accuracy with their intense need for flexibility.

Majority of these systems dispense arcs, beads, dotted lines and circles. When the system is able to automate multiple tasks for an initial investment, this can lead to quicker ROI. Nevertheless the flexibility of the application methods is a rather big challenge for the robotic systems.

Good qualities of a perfect Robot Integrator

What are the few things that you should watch out for while choosing a robot integrator for an adhesive dispensing system? Here are few factors to check:

- Experience in the industry: The foremost thing that you should watch out for is its experience in the industry. You should know what the automated system mean to your business and how it assists you in competing with others.

- Collaboration and support: Your robot integrator needs to be a perfect business partner which understands how the system will have an impact on the present operations. Moreover, you would definitely want an integrator which offers programming before installation, training and constant maintenance.

- Robot components: There are several instances where manual processes are automated and this lowers the initial cost of automation, which thereby reduces integration lead time. Overall, this proves to boost productivity in similar cases.

Apart from the above mentioned 3 qualities, there are certainly various other qualities which distinguish the best robot integrators from the worst ones. You have to be committed to the service to make sure you get the best robotic adhesive dispensing system.

In a nutshell, robotic adhesive dispensing systems need high levels of consistency, accuracy and flexibility in order to be constructive. If you can choose the best integrator, you may choose the system based on the above listed qualities to ensure best performance.