HACCP (Hazard Analysis and Critical Control Points) is the standard for food safety in the US and around the world. It comprises seven principles growers, processors, and manufacturers must follow to ensure that food is safe. HACCP protects the food supply from chemical, physical, and microbiological hazards.

In this blog, we’ll share a brief history of HACCP, explain why every food organization needs to get HACCP right, and look at the seven guiding principles of HACCP.

Let’s dive right in!

A Quick History of HACCP

HACCP started not because of work on the ground, but because of work in outer space. The National Aeronautics and Space Administration (NASA) was planning for the Apollo 11 lunar landing. But astronauts need to be fed, too. So, scientists at NASA got together with scientists from Pillsbury to develop a system for making the food on Apollo 11 very safe.

On Apollo 11, food safety was even more important than anywhere on earth. There was no doctor, no advanced medical facilities. There wasn’t even a toilet! Even slight food poisoning would have had dire consequences. Pillsbury and NASA developed policies and procedures to ensure the safest possible food on board Apollo 11, and the beginnings of HACCP took shape.

A subsequent contamination of baby food at Pillsbury inspired a NASA scientist to suggest to Pillsbury that the codified food regulations the two parties had created be used at Pillsbury to ensure greater safety. And over the next decade and a half, HACCP went from being meant for a single application to being a globally accepted standard for quality food.

Dickson has more on the history of HACCP in its guide.

Why You Need to Get HACCP Right

It might seem obvious, but if you’re a producer in the food supply, you must get HACCP right. The principles of HACCP have reduced biological, chemical, and physical contaminants in the food supply significantly. It has led from a time where it was expected that food would be dangerous to a time where food recalls are relatively rare and, thus, make national news.

In the US, the standards of HACCP are included in federal laws. Until recently, these principles didn’t apply to every food group. They’ve been built upon with the Food Safety Modernization Act. Signed into law in 2011, this act builds on HACCP and gives the FDA (Food and Drug Administration) more power to oversee how food is produced, processed, and distributed.

Not only is getting HACCP right the law, but it’s the right thing to do to keep everyone safe at the dinner table.

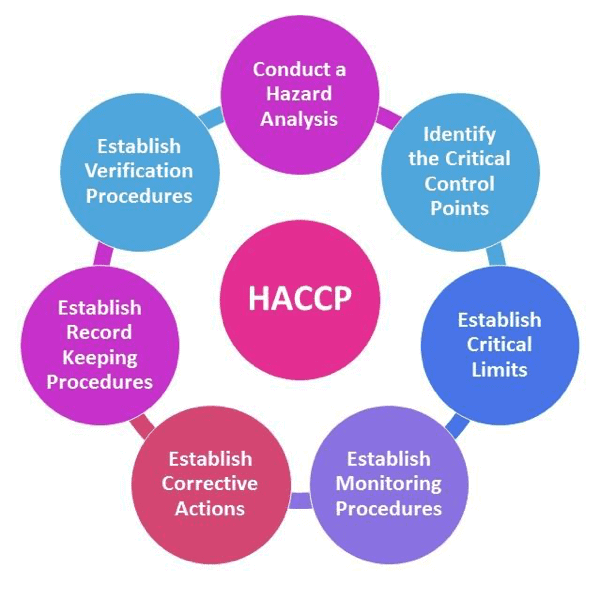

The 7 Principles of HACCP

The seven principles of HACCP form a path for every producer, processor, and distributor to create a HACCP plan that details what is being monitored, how it will be monitored, and how to handle safety violations.

In most cases, a HACCP committee puts together a HACCP plan. This committee works together to follow the principles, decide courses of action, and follow through on maintaining the program.

Here are the seven principles of HACCP. Following them helps ensure a higher level of safety and quality in the food production chain.

Principle #1: Conduct a Hazard Analysis

The committee reviews the entire production process to look for places where hazards might occur. For example, one hazard might exist in the bottling area with possible contamination of foodstuffs by broken glass.

Another might be in the warehouse where temperatures must be maintained. While every hazard must be documented, they will not all be included in the ultimate plan. If the team excludes a hazard, they must document the hazard and the reasoning for excluding it.

Principle #2: Identify the Critical Control Points (CCP)

Critical control points (CCP) are those points in the process where hazards can be reduced. Some CCP will reduce several hazards at once. Sometimes, it will take several CCP to avoid a single hazard. For example, the hazard of time-temperature abuse of food is often controlled at several points along the process.

Hazards cannot be completely eliminated, but all hazards should be mitigated to an acceptable level. The team uses a CCP decision tree to decide where the CCPs are and what hazards they control.

Principle #3: Establish Critical Limits

A critical limit (CL) is the amount by which a contaminant must be controlled to prevent a food safety hazard. There are usually minimum and maximum allowable limits.

The factors that are controlled are often temperature, humidity, pH levels, moisture, weight, and other factors. Each factor needs to be measurable and definable.

Principle #4: Monitor CCPs

A major factor in the process is determining how a CCP will be monitored, who will monitor it, and how they will record the information. Decisions such as how often data needs to be retrieved also factor into the process.

Very often, data loggers (digital data loggers) track these environmental factors automatically now. This has reduced the amount of effort humans need to put in to gather this data and it eliminates human error almost entirely.

Principle #5: Establish Corrective Actions

For every CCP and every potential hazard, a corrective needs to be included. These procedures not only correct a one-time issue but should build into the HACCP plan a system for converting a one-time correction into a permanent correction.

An example of this again can come from temperature monitoring in a storage area. If the area is too warm, the corrective actions might be to hand temperature test some of the food, have the cooling units maintained, and look for hot spots using data loggers.

Principle #6: Verification

The system creates a set of procedures that monitor those parts of the plan that aren’t in direct observation. Usually this involves audits of logs, incident reports, etc. Maintenance items, like instrument calibration and product testing, are included at this stage.

Again, data loggers have become an indispensable part of this work. They can be placed everywhere from the cold air vents to the floors to being licensed in boxes of food. They feed information into a single computer program that gives the HACCP manager instant access to data.

Principle #7: Record Keeping

All the records from the establishment of the plan to every scrap of monitoring data should be kept. Paper records were difficult to preserve and maintain. Today, everything is kept in cloud-based files.

If a problem is discovered down the road, sometimes months later, this historical data allows management to trace the problem backward to the point at which a hazard entered production.

HACCP is the International Standard

HACCP is now the international standard for food safety. Each of these steps, whether presented under the name HACCP or not, are at the heart of all food safety monitoring and production.

Getting HACCP right is an imperative for every food producer, handler, shipper, or seller. In the most literal sense, lives are at stake.