Online you can find so much information nowadays. It is even possible to outsource your newest project to an online machine shop for example. On top of that, you can also watch videos on YouTube about 3D printing, which can be done by an online service as well.

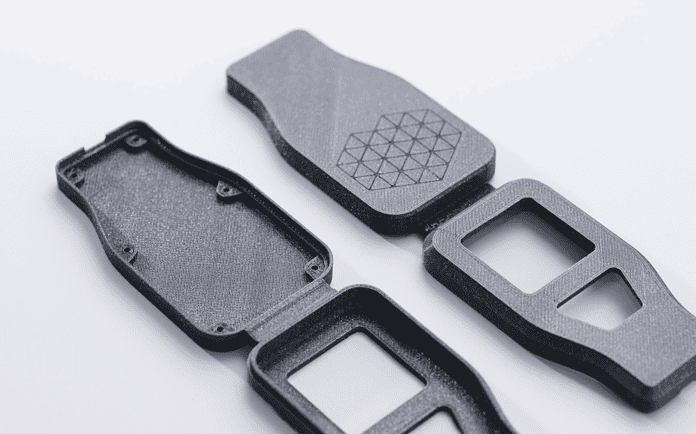

They can create products with the help of a technique called FDM 3D printing, although other processes can be used as well. When using FDM 3D printing it is important that the end print is strong, which can be achieved with the tips mentioned below.

Also be sure to use the help of the experts of a 3D printing service to create a strong part.

No Cooling

Not all materials can be FDM 3D printed with cooling, but for those materials that can be printed like this, such as PLA, this is a very useful feature. This is the case since cooling is very helpful in improving surface quality, especially for protruding parts, but it turns out that it is detrimental to the strength of the parts unfortunately.

Good layer adhesion requires that the printed layer and the previous layer completely melt together, which is more difficult to achieve when each layer is actively cooled by the 3D printer.

If the geometry of the part allows zero cooling, turn off the fan for the best level of intercoat adhesion. If cooling is required, set it to the lowest power, which will still produce the desired surface quality.

Higher Extrusion Width

A higher extrusion width increases the resistance to 150 percent to 200 percent of the nozzle diameter. Adjusting this setting increases the flow rate to achieve the desired width, which does two things. Firstly, it deposits more material per pass.

On top of that, increased downward compression pressure to help the printed layer adhere to the previous layer. As is shown in videos on YouTube, increasing the extrusion width will make the FDM 3D printed part stronger.

Furthermore, it also leads to less material used, while the printing time gets lowered by it as well. In other words, by adjusting just one single parameter, you can achieve three upgrades relatively simply.

Adjust Basic Settings with FDM 3D Printing

Another video you can find on YouTube covers the basics you have to use to create stronger FDM 3D prints. There are several slice settings to change the strength of a product that is going to be FDM 3D printed, including the fill percentage, the surface thickness, the layer height, and the width of the extrusion for example.

But one configuration that is often overlooked is the so-called infill overlap, which affects the degree of integration between the perimeters and the infill. Usually only a small increase is required to make the print a lot stronger.

It is definitely advised to at least once try this tip to examine if it actually made your created product a bit stronger, which will also be the case when using the other tips.